|

|

|

|

|

Old garage level with drive. |

Look where the consumer unit was, I had to move it ten feet, and this was the job ELECSA were using to my yearly check up on! |

Back of old garage |

Solid concrete raft to build on, but had to go lower with outer skin to meet building Regs |

|

|

|

|

|

| Battened out the wall & filled with 80mm QuinnThem |

the gas service pipe could'nt be moved so I took it upon myself to cover it with a 6mm steel plate! |

Due to lateral loading, I couldn't have two seperate doors side by side, so I made one big one without a pillar |

Then put a wall down the centre of it, hey presto, two seperate door ways! |

|

|

|

|

|

| I had to install a new 25mm twin core SWA along the exterior side of the house with an added HBC switched DP 80 amp fuse for cable protection (regs) |

cable entry down to where the new utilty room was to be constructed. I made a map of where evey cable came from, these are just a few! |

SWA terminated & existing consumer unit re-used as it was 17th Ed. I also installed an extractor while I was up there. This is where my electrical training & part P is very useful |

See the four holes in the plaster board wall, over and under the first fix socket outlets? |

|

|

|

|

|

Do you like my tubes! The customer was installing a plasma on the other side of the wall & wanted the cables to be hidden away, so I made these ducts from downspouts! |

Building the utility room dividing wall & installing soft insulation |

View from the hallway. There used to be one door into the garage with a step |

I jumped the gun a bit here to show a before & after shot |

|

|

|

|

| I got the ashpalters in before I built the outer wall to make things easier |

A great shot of the toothing out |

Bricks & stone work cills matched and being laid |

Starting the dry lining |

|

|

|

|

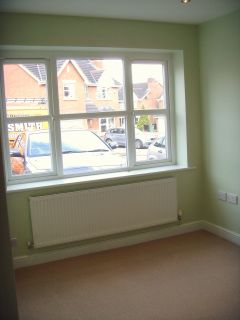

| The radiator I fitted with concealed pipework & no ugly boxing in! |

Plasma ready to go on & door to be put back after the carpet fitters |

Before |

After |